Description

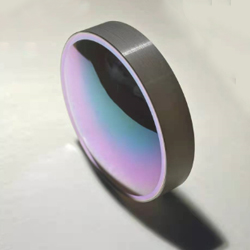

Chalcogenide Glass

Chalcogenide glass is an infrared material with excellent transmittance within the wave band from 1 to 16μm. It has stable chemical property and high acid resistance. It can also eliminate color difference in the infrared optical system.

Thus it is the material of top choice for infrared lens via compression molding. Through independently innovated glass synthesis technology, Baoding Jingze Company can produce workblank and plain film with maximum diameter of 120mm.

Application of chalcogenide glass 5.1 infrared optical elements

Application of chalcogenide glass 5.1 infrared optical elements

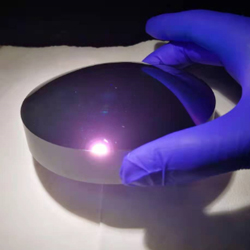

As chalcogenide glass has wide scope of infrared transmission, it varies with the glass composition. Its transmittance can be expanded from 2μm to 14-18μm. Thus chalcogenide glass can be applied in such aspects as thermal imagery, night vision, transfer of CO2 laser energy, analysis of chemical sensing, and radiation thermometer.

The chalcogenide glass that takes the lead in having commercial purpose is bock arsenic-sulfur glass. In the 1950s, it is mainly used for the optical material of the infrared region. In the 20 years that followed, other types of Sulphide glass, selenide glass, and the selenium antimony glass used for far infrared region were put into practical commercial use.

The applications of these materials in the infrared region include energy control, hot spot detection, circuit test, temperature monitoring, and night vision. Taking night vision for example, the radiation wavelength of general objects and human ranges from 8cm to 12cm.

The transmittance scope of selenium antimony glass is fit for the thermal imagery in this region very much.

Sulfur compound glass, also referred to as chalcogenide glass, is a type of glass taking sulfide, selenide, and hoof compound as main component and including compound glass of the sulfur oxide series containing oxide.

It is characterized by low specific resistance, the property of switch and memory, the transmitting infrared wave up to over 2DF}m, low melting and softening temperature, resistance to acid medium and even the corrosion of hydrofluoric acid.

As an important type of transmitting infrared glass, it can be used both as optical storage material and acoustooptic modulated material as well as as glass of low melting point.

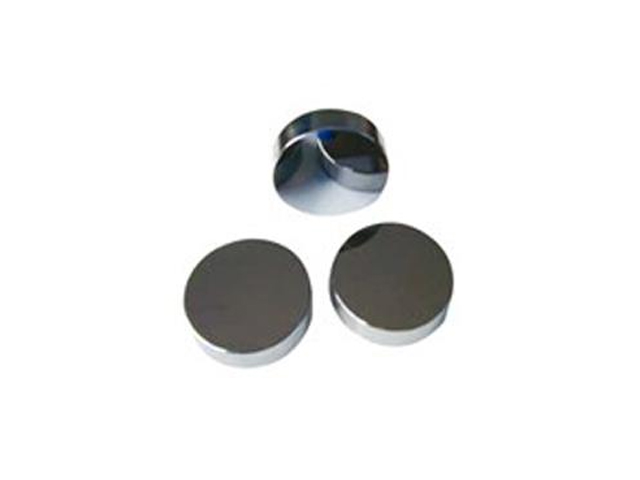

Processing parameters

Processing parameters

Parallelism:< 3 arc minutes

Tolerance:±0.02 – ±0.1mm

Flatness:λ/4 per inch @633nm

Surface quality:20 – 10