Description

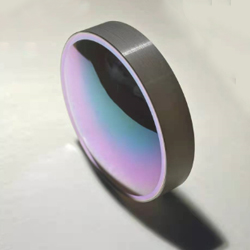

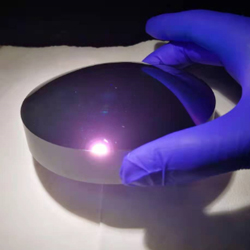

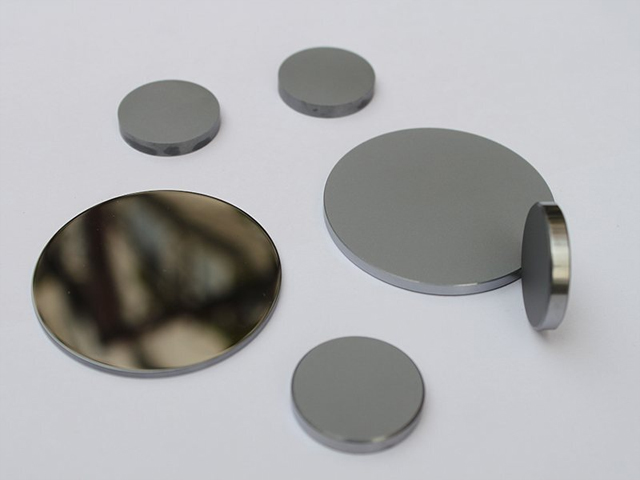

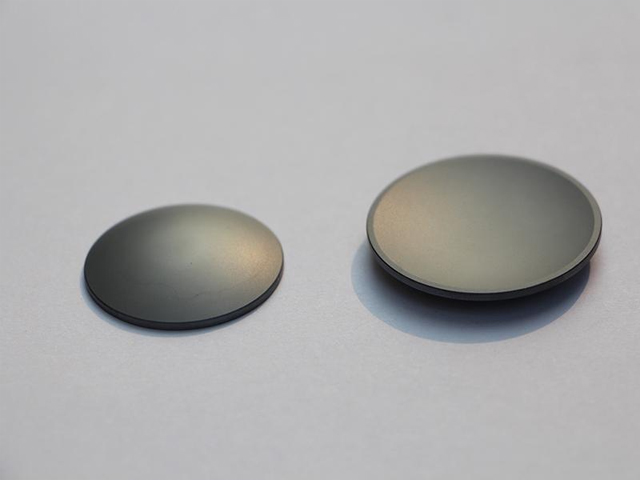

Silicon polished sections are widely used in various fields of semiconductors. We have the ability to process 2-8 inch semiconductor monocrystalline silicon wafers, The quality of our products is checked at all levels, in the hope of providing customers with the highest quality products.

Silicon polished sections are widely used in various fields of semiconductors. We have the ability to process 2-8 inch semiconductor monocrystalline silicon wafers, The quality of our products is checked at all levels, in the hope of providing customers with the highest quality products.

| Name | Silicon wafer |

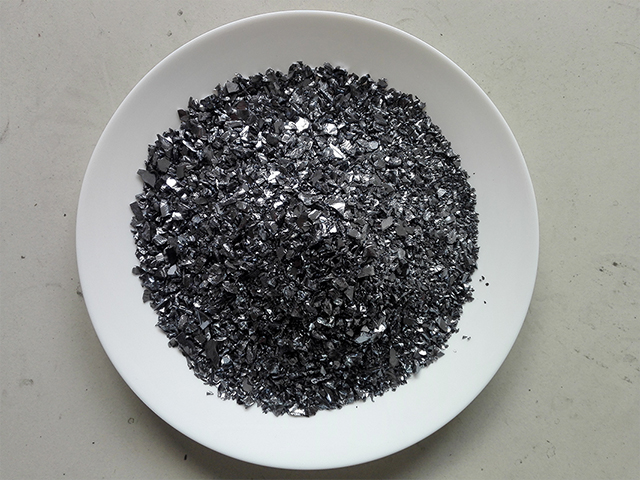

| Growth Pattern | CZ or FZ |

| Type | P or N |

| Orientation | <100>or<111> |

| Diameter | 2-8 inch |

| Tolerance | ±5mm |

| Thickness | 180-2000μm |

| Tolerance | ±10μm |

| Dislocation Density(pcs/C㎡) | None |

| Resistivity | 0.001-10000 Ω.cm |

| Purity | 6N-9N |

| PARAMETER | UNIT | KORVXQ2B |

| GRADE | Prime | Prime |

| GROW METHOD | CZ | CZ |

| TYPE | P | |

| DOPANT | Boron | |

| XTAL ORIENTATION | DEGREES | 1-0-0 |

| RESISTIVITY CTR | W·CM | 10.0-20.0 |

| RRG 1 CTR-1/2R MAX | ﹪ | / |

| RRG 2 C-6mm MAX | ﹪ | 8.0 |

| SLICE ORIENTATION | DEGREES | 1-0-0±0.5° |

| OXYGEN CTR | NEW PPMA | 13.0-19.0 |

| ORG MAX | ﹪ | / |

| PRIMARY FLAT LOCATION | DEGREES | 1-1-0±0.5° |

| PRIMARY FLAT LENGTH | MM | 32.5±2.5 |

| SECONDARY FLAT LOCATION | DEGREES | N/A |

| SECONDARY FLAT LENGTH | MM | / |

| CARBON CTR MAX | PPMA | 1.0 |

| TTV MAX | MICRONS | 15.0 |

| BOW MAX | MICRONS | 40.0 |

| WARP MAX | MICRONS | 40.0 |

| EDGE CONTOUR | SEMI STD. | |

| FS PARTICLE | LIGHT | / |

| SIZE MAX | MICRONS | 0.5 |

| MAX | #/SL | 10.0 |

| DISLOCATION | #/Sq c㎡ | 100.0 |

| OISF MAX | #/Sq c㎡ | 100.0 |

| LASER MARK | N/A | |

| GLOBAL TIR MAX | MICRONS | 5.0 |

| SITE TIR MAX | MICRONS | / |

| SLICE BACK | Etched | |

| CUSTOMER PART NO | 4-thk1000-ssp | |

| PACKAGE | standard packaging | UPACK A 25片/box |

| REMARKS | Other unlisted parameters are executed according to SEMI standards | |